COLLEGE PARK, Md. — Researchers at the University of Maryland are in the lab developing ways to address the nationwide shortage of masks, and they are on the fast track to developing solutions. The scientists are working with several local hospitals and have come up with a way to not only sterilize disposable masks but create custom, resuable masks.

Bill Bentley, Director of the Robert E. Fischell Institute for Biomedical Devices at the University of Maryland, said UMD’s scientists are developing ways to help first responders on the front lines of the COVID-19 pandemic.

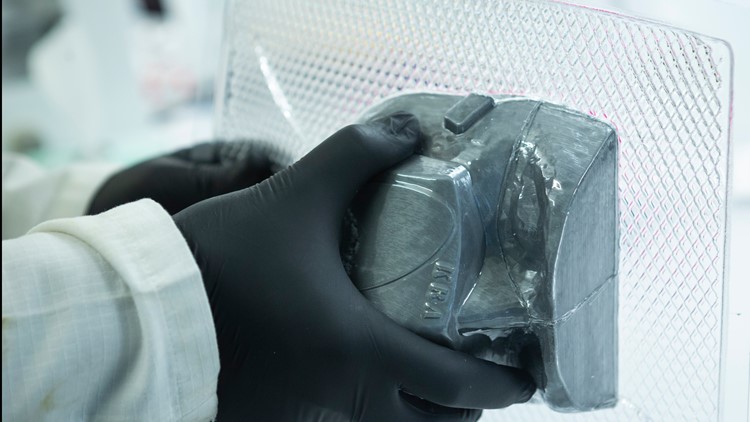

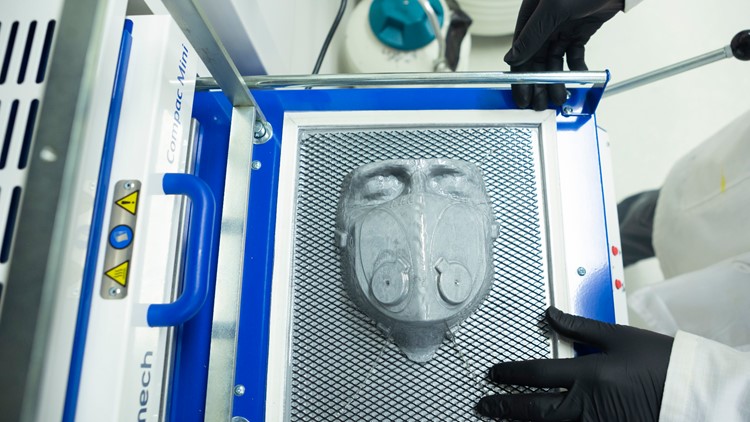

The first project is custom masks. Medical staff would scan his or her face, then UMD researchers in the lab would use a 3D printer to develop a mask that is a perfect fit for each individual.

"The mask itself could be washed, then the filter media could be affixed," Bentley said.

UMD's lab is also working on a method to sterilize disposable masks.

Researchers developing masks in UMD lab

Researchers are working around the clock to get to these solutions quickly and safely.

"A lot of people have an interest and desire to help, and that’s important to have that," Bentley said. "But one of the things we’re trying to do is the test that would normally run to ensure the safety of the clinician is still being done so the solutions we propose will not harm the patient or the clinician."

Bentley said the custom-made masks are ready to go and they’ve already delivered nine. He said the sterilization process that allows hospital workers to re-use disposable masks still needs some fine-tuning, but should be ready in about a week.

"It’s incredibly satisfying not only to people in our institute, but the people we are communicating with to think that we’re actually going to help in a very near time,” Bentley said.

RELATED: Obama praises 7-year-old Fairfax Co. boy who donated 6,000 masks, gloves, shower caps to hospital